The warehouse management software with many integrations like in - Courier, Online shopping platforms, fulfillment customers, Customs related customers, online retail customers, and so on.

The warehouse management software with 150+ integrations

Courier integrations

Online shopping platform integrations

3PL and Fulfilment customers

Online retail customers

Warehouse Management Software

The top WMS for wholesalers, retailers, customs, and online shopping

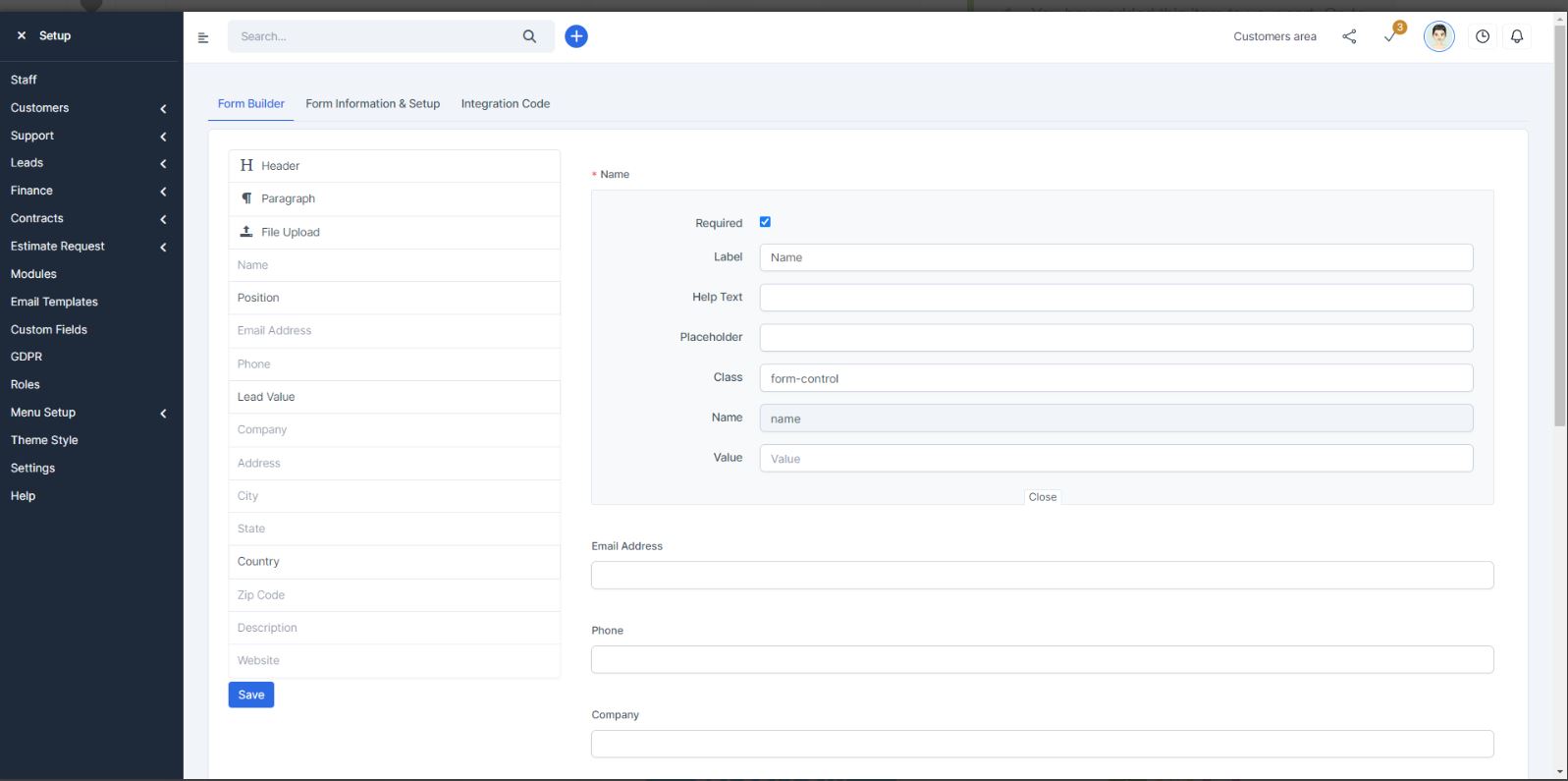

Please Submit the below form to download the Advanced CRM Docs

WMS software

What are the benefits of WMS software?

Automate your warehouse

Automate warehouse operations so that operators can operate more productively while receiving real-time updates.

Optimise warehouse space

By controlling inventory and making the best use of your warehouse space, automated advanced location management enables you to grow your company.

Advanced warehouse management

Enhance the control of your workflow with features like stock counts, cycling, and support for pallet and cartons.

Real time reporting

With robust reporting capabilities that are available anywhere, anytime, and provide real-time information on orders, inventory, and shipments, your firm will gain confidence.

Boost productivity using barcoding software: The mobile scanning app is usable on a variety of compatible devices and can be used as effective warehouse management.

![]() Multi-type Barcode Picking: The programme offers a variety of batch-driven barcode picking options to accommodate different order types in logical location order for maximum efficiency and accuracy.

Multi-type Barcode Picking: The programme offers a variety of batch-driven barcode picking options to accommodate different order types in logical location order for maximum efficiency and accuracy.

![]() Using our software: You can process products quickly, easily, and accurately. Simple stock booking, receipting, and comparison to previously issued ASNs or Purchase Orders.

Using our software: You can process products quickly, easily, and accurately. Simple stock booking, receipting, and comparison to previously issued ASNs or Purchase Orders.

![]() Transfer Merchandise: Effortlessly transport stock, whether in entire pallets or as individual units, from one place to another.

Transfer Merchandise: Effortlessly transport stock, whether in entire pallets or as individual units, from one place to another.

Sophisticated multi-location management

Utilize our cloud-based WMS software’s location management tools, which allow a single or several warehouses, to manage stock locations and capacity:

![]() Multiple Stock Locations: For pick management, replenishment, and bulk storage, assign various stock locations to various product lines. Splitting and dividing picking tasks effectively among your warehouse personnel is made possible by location zone management.

Multiple Stock Locations: For pick management, replenishment, and bulk storage, assign various stock locations to various product lines. Splitting and dividing picking tasks effectively among your warehouse personnel is made possible by location zone management.

![]() Location Labeling: For thermal or laser printers, bulk print location ID barcode labels in any style and size.

Location Labeling: For thermal or laser printers, bulk print location ID barcode labels in any style and size.

Professional inventory tracking

Our warehouse inventory management software is adaptable and can handle specialised inventory categories.

![]() Best Before Dates: Our WMS offers perishable product stock allocation management with custom expiration date warning notifications that is automatic and FIFO.

Best Before Dates: Our WMS offers perishable product stock allocation management with custom expiration date warning notifications that is automatic and FIFO.

![]() Take charge of lots and batches: Tracking which batches have been dispatched to particular clients can help you ensure that every item of inventory that passes through your warehouse can be traced back to its group of origin in the event of a product recall.

Take charge of lots and batches: Tracking which batches have been dispatched to particular clients can help you ensure that every item of inventory that passes through your warehouse can be traced back to its group of origin in the event of a product recall.

![]() Serial Information: When sending out high-value goods, include individual serial number tracking, such as IMEI numbers for high-end mobile phones.

Serial Information: When sending out high-value goods, include individual serial number tracking, such as IMEI numbers for high-end mobile phones.

![]() Complete Audit Trail: Every stock transaction is completely auditable. Every stock transaction is recorded together with the customer name, order ID, and operator who executed the transaction. All of these can be quickly exported to Excel for reconciliation.

Complete Audit Trail: Every stock transaction is completely auditable. Every stock transaction is recorded together with the customer name, order ID, and operator who executed the transaction. All of these can be quickly exported to Excel for reconciliation.